Project Overview

This project, undertaken for the PLAS.5180 Plastic Part Design course, involved a comprehensive design and analysis process for the plastic components of a household fan, with a primary focus on suitability for injection molding. The team systematically addressed various stages from conceptualization to final design validation, including CAD modeling, material selection, detailed moldability simulations using Autodesk Moldflow Insight, assembly considerations, and structural analysis.

A physical example of the type of fan analyzed, highlighting the real-world application of the design principles.

I. Application and Component Design

The project began by understanding the fan’s core function: converting electrical energy into mechanical energy for airflow to cool a space. Key plastic components were identified and designed/reverse-engineered, likely using CAD software like SolidWorks.

Key Plastic Components Detailed:

- Knob

- Side-Clip

- Front Fan Shroud

- Wire Cover

- Legs (Stand)

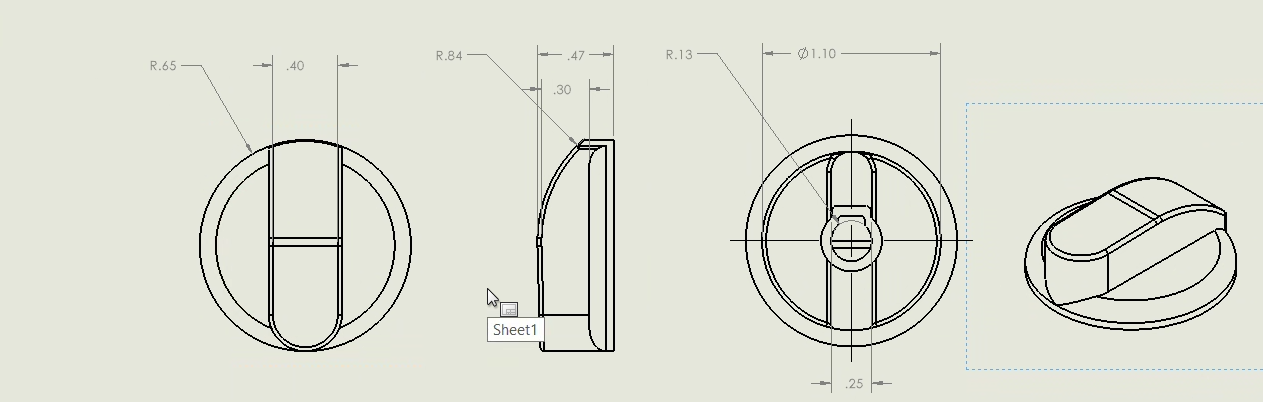

Engineering drawing of the fan knob, showcasing dimensional details.

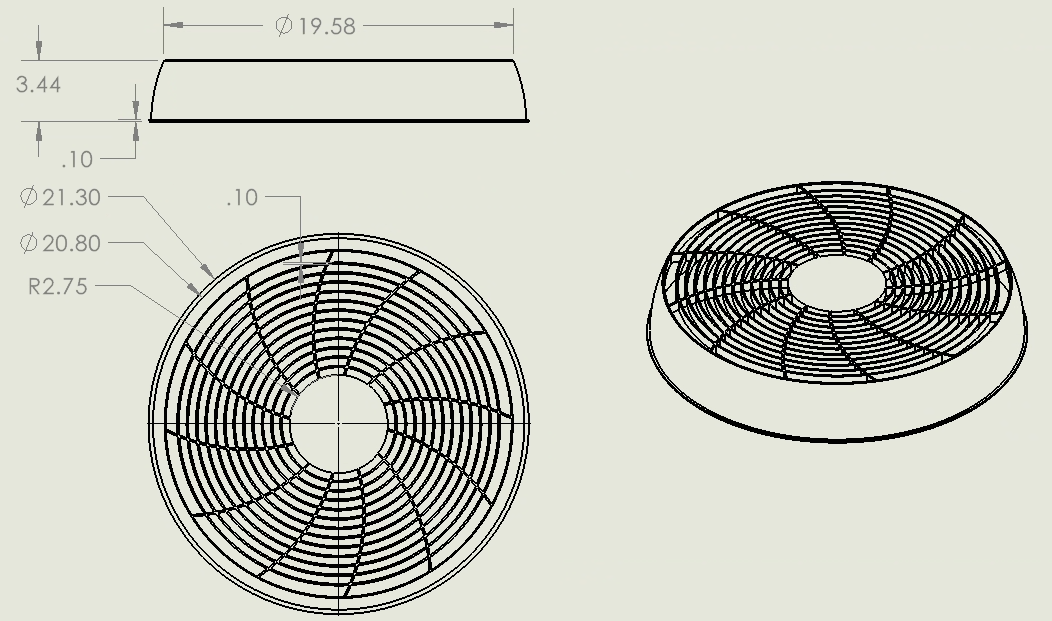

Detailed CAD drawing of the front fan shroud, a critical component for safety and airflow.

II. Material Selection Process

A crucial phase was selecting the optimal plastic material based on the fan’s end-use requirements: durability, strength, manufacturability, cost, and lifespan.

Requirements Considered:

- Durable enough to withstand minor falls.

- Blades strong enough for effective air fanning.

- Capable of long operational periods.

- Long-lasting over several years.

- Able to run at full speed without breaking.

Two primary materials were evaluated: Polycarbonate (PC) and Polypropylene (PP).

Polycarbonate (PC) pellets. PC was evaluated for its high durability and strength.

Polypropylene (PP) pellets. PP was considered for its cost-effectiveness and ease of molding.

Material Comparison (PP vs. PC):

- Molding & Machining: PP is significantly easier to machine and mold.

- Weight: Both are light, but PP is lighter.

- Cost: PP is considerably cheaper for molding.

- Electrical Properties: Both are good non-conductive insulators.

- Typical Applications: PC for heavy-duty items (roofing panels, lenses); PP for consumer goods, bottles, medical equipment.

Conclusion: Polypropylene (PP) was selected as the more suitable material. Reasons:

- Sturdy enough for airflow and long run times.

- Much easier to mold than PC.

- Cheaper than PC.

- Durable with good impact resistance.

III. Moldability Analysis

This formed a core part of the project, assessing how well the designed parts could be manufactured via injection molding.

Physical Inspection of Molded Features:

Existing fan components were examined to identify common injection molding characteristics.

- Gate Types: Pin-point gates (Knob, Side-Clip, Leg/Wire Cover) and Sprue gates (Leg section, Shroud center) were observed.

- Mold Type: Evidence of thermal pin-point gates, hot runner molds (for knob/clip), and 2-plate cold runner molds (for larger parts) was noted.

- Ejector Pins: Marks were visible on various components.

- Parting Lines: Clearly identified on all major parts, indicating where mold halves meet.

Example of parting line identified on fan base component, crucial for mold design.

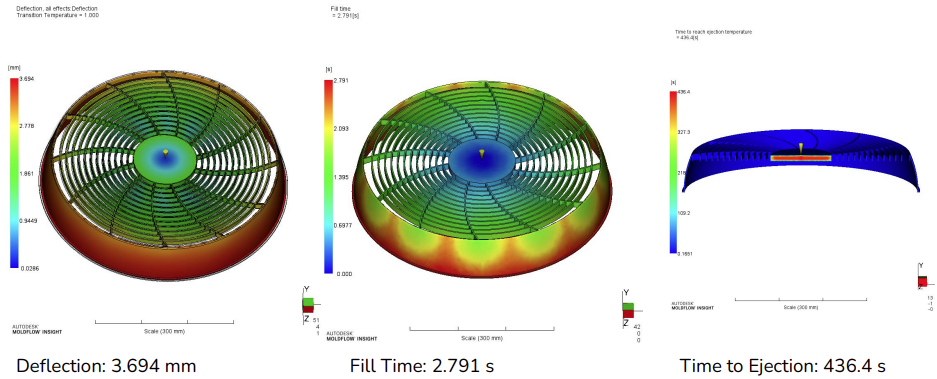

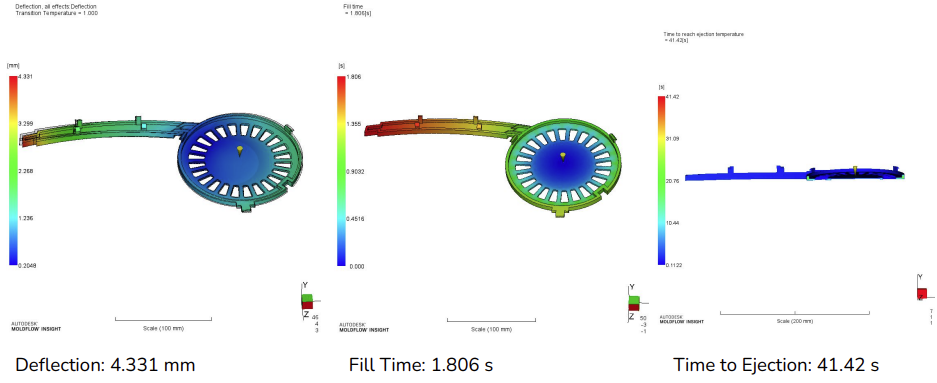

Injection Molding Simulation (Autodesk Moldflow Insight):

Simulations were performed for key PP components to predict manufacturing behavior.

Table: Summary of key Moldflow simulation results for selected components.

| Component | Deflection (mm) | Fill Time (s) | Time to Ejection (s) |

|---|---|---|---|

| Knob | 0.2550 | 0.0911 | 21.07 |

| Side Clip | 0.3761 | 0.6159 | 19.65 |

| Fan Shroud | 3.694 | 2.791 | 436.4 |

| Wire Covering | 4.331 | 1.806 | 41.42 |

| Fan Leg | 5.994 | 3.342 | 37.05 |

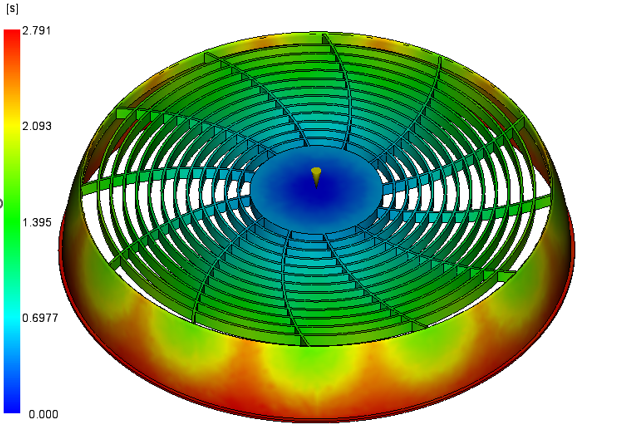

Moldflow simulation results for the Fan Shroud, showing Deflection, Fill Time, and Time to Ejection.

Moldflow simulation for the Wire Cover, highlighting it as the part with the highest deflection and fill time.

Moldability Highlights:

- Highest Deflection: Fan Leg - 5.994 mm

- Highest Fill Time: Fan Leg - 3.342 s

- Highest Time to Ejection: Fan Shroud - 436.4 s These results pinpoint areas potentially needing design optimization or careful process control.

IV. Assembly Features and Considerations

The design also focused on ease of assembly and serviceability.

- Assembly Method: 9 main parts (legs, shrouds, motor, control panels, knobs, wire cover).

- Key Features:

- Snap fits (shrouds, wire cover) for simple assembly.

- Pass-through core and slide-activated inserts.

- Mechanical fasteners with molded screw bosses (self-tapping, no in-mold hardware).

- Press-fit knobs and fan blades onto metal/plastic motor shafts.

- Disassembly: The front cover can be removed independently for service.

- Overall: Good use of snap fits where possible, with screw bosses for other connections.

Close-up views of assembly features like snap-fits and press-fit components.

V. Structural Analysis

A basic structural integrity check was performed, focusing on the fan legs.

Points of Failure Identified:

- Knobs for speed adjustment.

- Motor and fan blade mounting point.

- Supports (legs) holding the fan housing (primary focus for analysis).

Calculations:

- Fan Mass (M): 3.42 Kg

- Total Force (Ftotal): 33.55 N

- Force per support (Fsupport): 16.775 N

- Polypropylene Yield Strength (σyield): 32 MPa

- Shear Yield Strength (τyield = σyield / √3): 18.48 MPa

Safety Factor Application:

- Material Utilization Factor (ST) = S1*S2*S3*S4 = 1.0 * 1.0 * 0.4 * 0.8 = 0.32

- S1 (injury risk): 1.0

- S2 (neat polymer): 1.0

- S3 (equations/no creep data): 0.4

- S4 (vibration degradation): 0.8

- Assumed Overall Safety Factor (k): ≈ 2

Design Stress vs. Actual Stress:

- Design Stress (τdesign = ST * τyield / k): (0.32 * 18.48 MPa) / 2 = 2.96 MPa

- Actual Stress (τactual = Fsupport / Area ≈ Fsupport / πr2): 2.12 MPa (based on assumed area)

Conclusion: 2.12 MPa (Actual) < 2.96 MPa (Design) -> The design does not fail under the analyzed static load.

Diagram illustrating the load application on the fan legs for structural analysis.

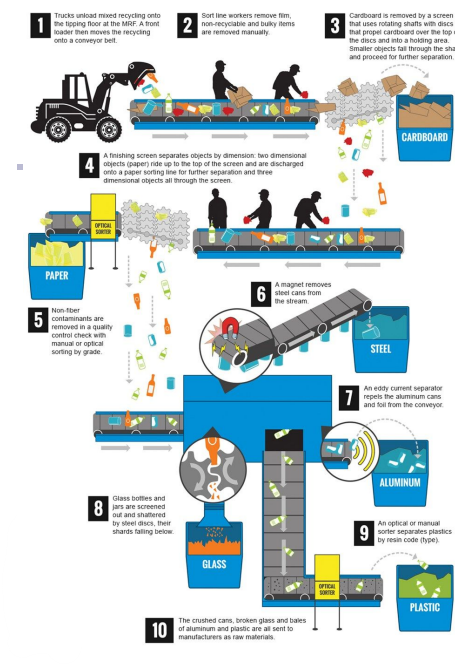

VI. Sustainability and Recyclability

Considerations for environmental impact:

- All major plastic pieces are made from the same type of plastic (PP), simplifying sorting.

- Motor and screws would need to be separated for optimal recycling.

- PP is a thermoplastic, making it inherently recyclable.

- Potential to use downcycled PP in manufacturing.

- Common uses of recycled PP include dairy/food containers, winter clothes, luggage, and furniture.

Infographic illustrating a typical plastics recycling process, relevant to the fan’s end-of-life.

Conclusion and Skills Demonstrated

This project successfully navigated the multifaceted process of designing plastic parts for an injection-molded fan. It showcased a practical application of engineering principles from material science to manufacturing simulation and structural validation.

Key Skills:

- Plastic Part Design: Understanding design considerations specific to plastics.

- CAD Modeling: (Implied) Use of software like SolidWorks for part creation.

- Material Science: Evaluation and selection of polymers based on application needs.

- Design for Manufacturing (DFM): Specifically for Injection Molding, including analysis of gates, parting lines, and ejector pins.

- Simulation: Proficiency with Autodesk Moldflow Insight for predicting fill time, deflection, and cooling time.

- Engineering Mechanics: Basic structural analysis, stress calculations, and application of safety factors.

- Problem Solving & Analysis: Identifying potential issues in moldability and structural integrity.

- Sustainability Awareness: Considering the recyclability and end-of-life of plastic products.

- Teamwork & Presentation: Collaborating and presenting complex technical information.