Project Overview & Client Objective

As a contracted Mechanical Engineer for Red’s Best, a seafood supplier in Boston, MA, I was responsible for designing and building a custom fish processing conveyor system. The project ran from October 2023 to June 2024, with the goal of creating a durable, food-safe, and space-efficient system to improve workflow. The objective was to deliver a fully functional conveyor system within a 9-month timeframe, meeting both client requirements and practical fabrication constraints.

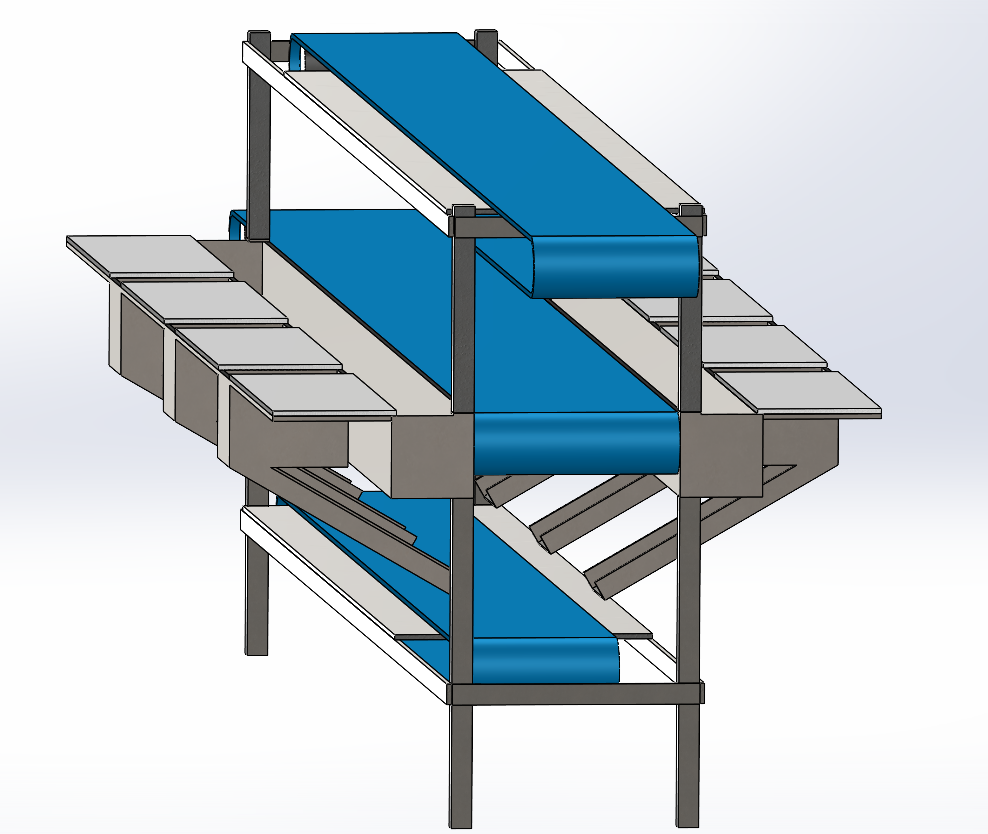

The completed multi-tier fish processing conveyor system installed and operational at Red’s Best facility.

I. Design and Development Process

The project encompassed the full lifecycle of mechanical system development, from initial design through on-site installation.

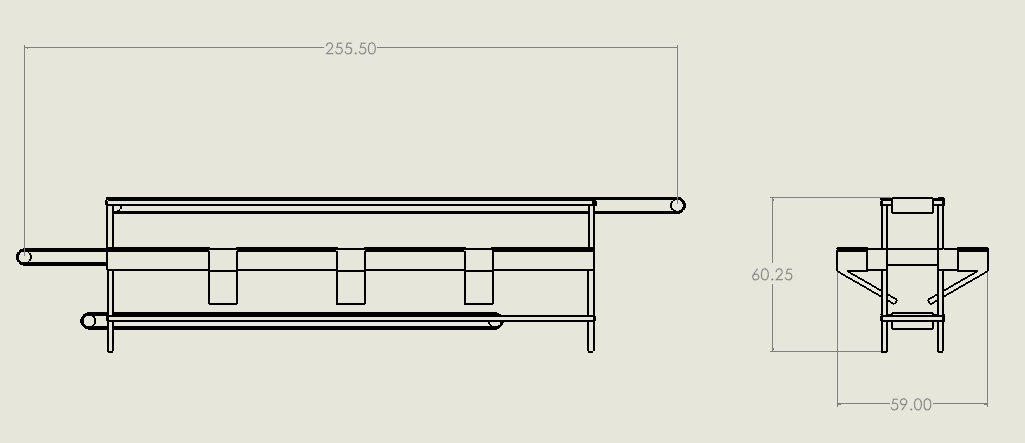

System Design in SolidWorks (Initial Design Pitch):

The conveyor system was modeled from the ground up in SolidWorks, including:

- Conceptualizing a multi-tier layout to optimize space and workflow.

- Creating an initial CAD proposal for client approval before detailing further.

- Modeling custom components such as frames, supports, and chutes, alongside purchased items like motors, gearboxes, and belts.

- Building assembly models to check fit, form, and function.

- Producing fabrication drawings to guide the build.

Isometric view of initial early version of the SolidWorks CAD model proposal, showcasing the multi-level design.

Orthographic views from the initial SolidWorks proposal, providing dimensions (Overall length approx. 255.50 inches, width approx. 59.00 inches, height approx. 60.25 inches).

Design Modifications & Iteration:

The design went through several iterations to incorporate client feedback, account for available materials, and simplify fabrication. This process refined the layout and ensured the final design balanced functionality with manufacturability.

Material Procurement & Management:

I helped manage procurement of all necessary materials and components, including:

- Stainless steel for structural and food-contact parts, chosen for durability and compliance with food processing standards.

- Modular conveyor belting, motors, and gearboxes sized for the application.

- Coordination with suppliers to ensure timely delivery and stay on schedule.

II. Fabrication, Assembly, and Installation

The project required both design engineering and hands-on fabrication.

Fabrication:

- Structural elements were cut, welded, and machined from stainless steel.

- Practical tolerances were considered, with oversized bolt holes and adjustment slots incorporated to accommodate variation from hand and shop-tool fabrication.

Assembly:

- The system was assembled by combining fabricated parts with purchased components.

- Alignment of conveyors and roller spacing were verified to ensure smooth operation and durability.

The conveyor system during the later stages of assembly and preparation for transport, highlighting the stainless steel construction and modular belting.

On-Site Installation and Client Collaboration:

- Once assembled, the conveyor system was transported to the Red’s Best facility.

- I coordinated the on-site installation, working closely with the client to position and integrate the system into their processing area.

- Final checks were performed to confirm full functionality and meet operational requirements.

III. Project Video

A video showcasing the fish processing conveyor system in operation at the Red’s Best facility.

IV. Conclusion and Key Skills Demonstrated

This contract project successfully delivered a custom conveyor system that improved workflow efficiency. It was completed on budget and ahead of schedule, demonstrating both technical design ability and practical execution.

Key Skills Demonstrated:

- Mechanical Design & CAD: SolidWorks modeling, assemblies, and fabrication drawings.

- Tolerance Considerations: Designing with practical clearances and adjustability for shop fabrication and assembly.

- Fabrication & Assembly: Hands-on experience welding, machining, and integrating mechanical systems.

- Material Selection: Stainless steel for durability and food-processing suitability.

- Project Management: Coordinating procurement, schedules, and design iterations within contract deadlines.

- System Integration: Combining fabricated structures with motors, conveyors, and controls.

- Client Collaboration: Communicating progress, incorporating feedback, and ensuring satisfaction.

- On-Site Installation: Leading transport, installation, and commissioning.

- Problem Solving: Adapting designs and overcoming challenges during fabrication and installation.