Executive Summary & Project Goal

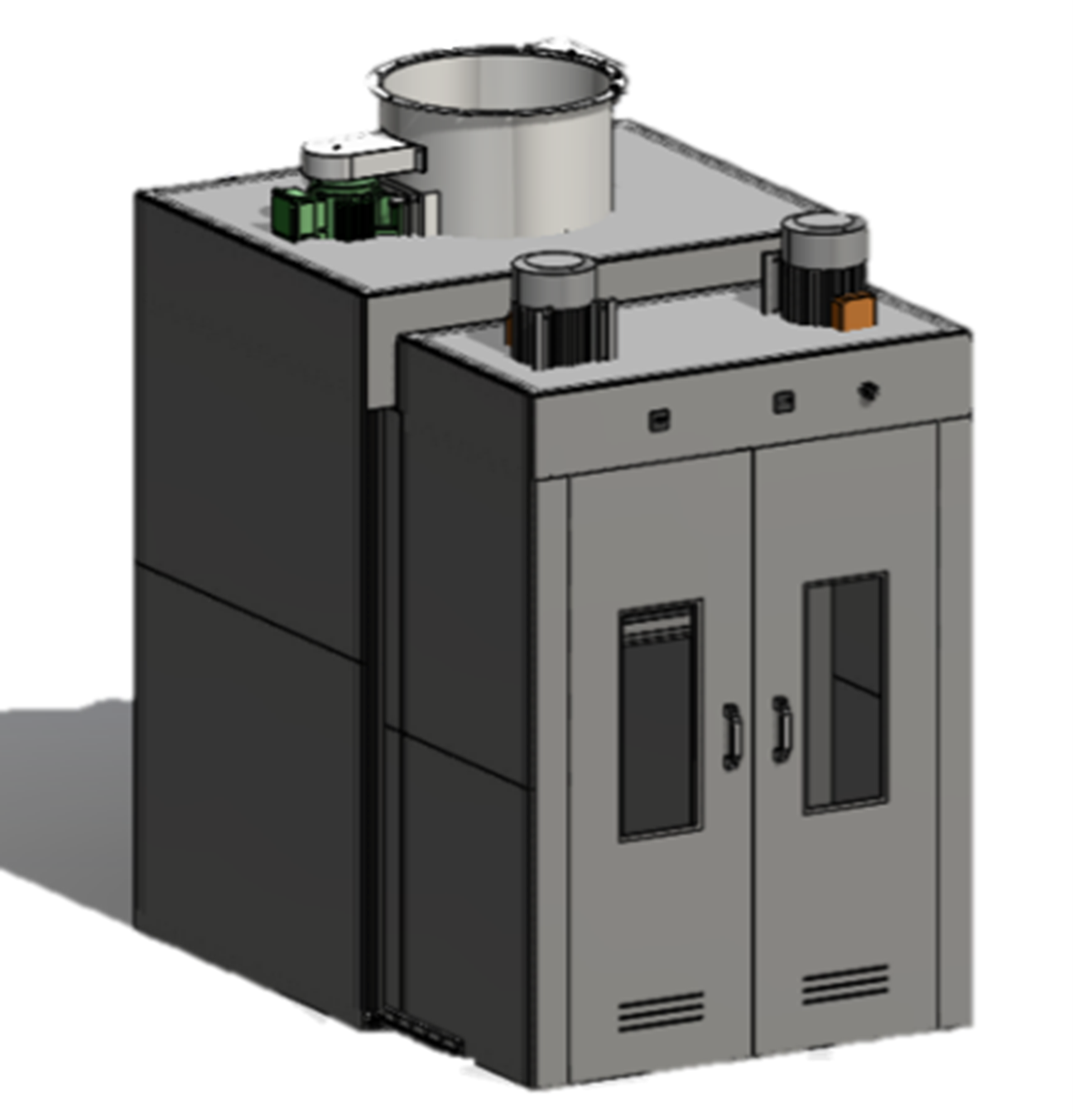

This Capstone Project, completed in partnership with Juniper Networks, focused on redesigning their existing Universal Hotbox (UHB) – a thermal test chamber used to screen networking equipment under controlled temperature conditions.

The Problem: Juniper’s UHBs were costly (approx. $20,000 each), difficult to ship, lacked adjustable depth for larger equipment, and offered a limited operator interface.

The Solution: A student team of Mechanical, Electrical, and Computer Engineers was tasked with creating a modular, palletizable design under $5,000, with adjustable internal depth, improved thermal control, and a user-friendly LabVIEW-based GUI.

Key Objectives:

- Reduce cost to under $5,000.

- Modular design for shipping on standard 48x40 in pallets.

- Adjustable internal depth in 12-inch increments.

- GUI for product selection and automated temperature control.

- Maintain 40°C for up to 24 hours.

CAD rendering of the proposed Universal Hotbox design.

I. Research and Background

The project began with a requirements review with Juniper and benchmarking of existing hotboxes.

Client Needs: The UHB must run 10–24 hour thermal soak tests at 40°C, be cost-effective, easily shippable, and handle various chassis sizes.

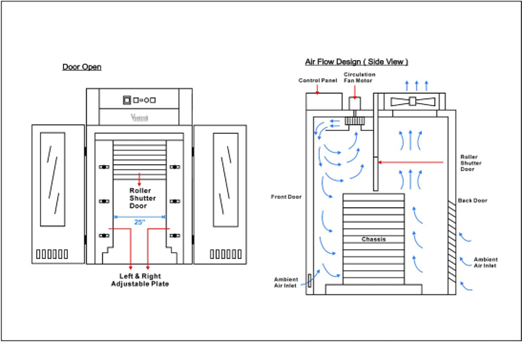

Existing Hotbox Study: The team evaluated a Vostron EVU128-60C-IT, analyzing airflow, insulation, and structure as a baseline.

Material & Component Research:

- Insulation: Retained glass wool for thermal properties and low cost.

- Panels: Switched from powder-coated steel to acrylic for visibility, fabrication ease, and insulation.

- Frame: Selected extruded aluminum T-slotted profiles for modularity and transportability.

- Product Dimensions: Gathered dimensional data from MX, PTX, and ACX product lines to define internal size and adjustability.

Airflow diagram of Juniper’s existing hotbox, used as a reference for redesign.

II. Design and Analysis

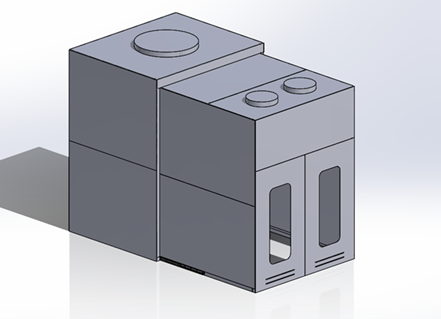

Mechanical Design – Roller Expansion Concept

Two telescoping shells (inner sliding within outer) enabled adjustable depth.

- Frame & Panels: T-slot aluminum with acrylic/PE sheets.

- Access: Clear acrylic doors, cable portals, and an internal roller door for section separation.

- Airflow: Combination of circulation fans and exhaust fans to ensure thermal uniformity.

CAD model showing the telescoping roller design for depth adjustment.

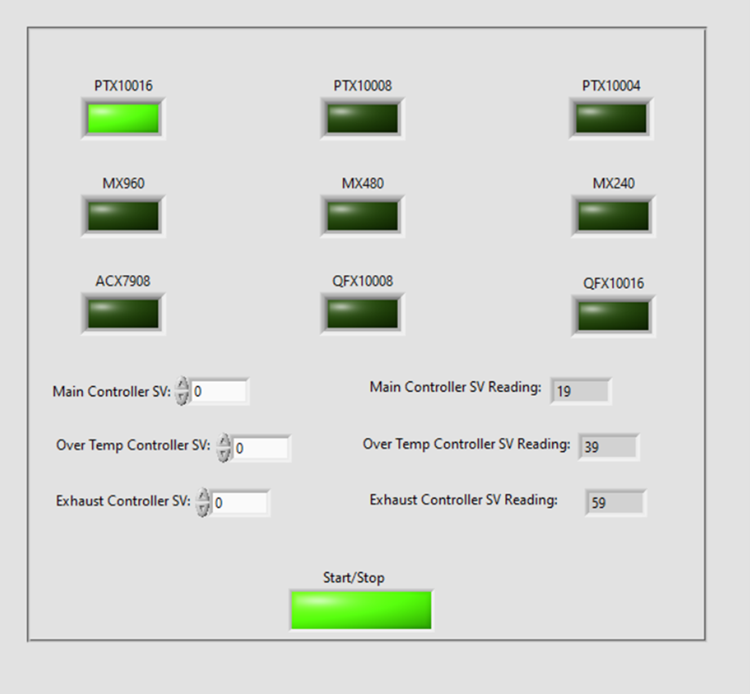

Software & GUI Design – LabVIEW

Developed a LabVIEW GUI for operator control and automated setpoint handling.

- Connected to Omron E5CC temperature controllers via RS485 Modbus.

- Arduino Mega 2560 interfaced with relays for fan/heater switching.

- GUI allowed operators to select a product, automatically adjusting control parameters.

LabVIEW GUI interface for operator control and monitoring.

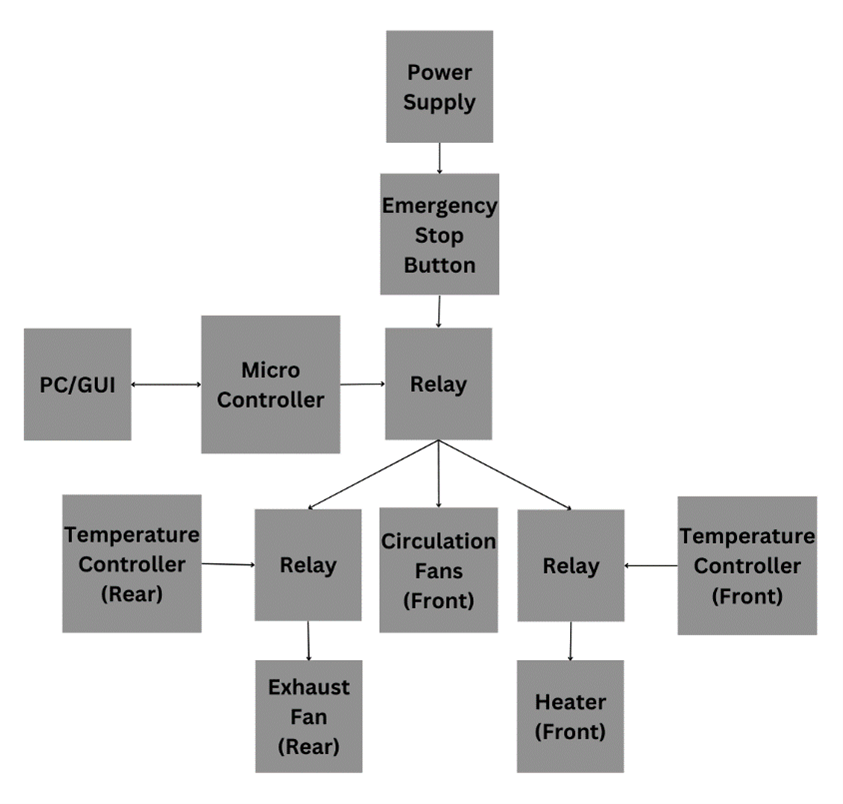

Electrical System

- Relays and transistor arrays switched high-power fans and heater.

- Independent control of front heating and rear exhaust for stable airflow.

- Safety features included breakers, overload relays, and emergency stop.

Electrical block diagram showing system power and control structure.

Cost Analysis

A detailed Bill of Materials brought the projected prototype cost to $4565.66, under the $5000 target.

Table 7 (from PDF Page 24-25): Budget / Finance - Full Bill of Materials

| Items | Quantity | $/unit | Price (USD) |

|---|---|---|---|

| Arduino 2560 | 1 | $57.30 | $57.30 |

| E5CC-RX2ABM-002 | 1 | $457.85 | $457.85 |

| USB A to USB B | 1 | $3.07 | $3.07 |

| E5CC-QX3A5M-000 | 3 | $274.02 | $822.06 |

| Power Cord | 1 | $7.93 | $7.93 |

| RS485 Communication Cable | 3 | $44.11 | $132.33 |

| Compact Spade Terminal Relays | 4 | $15.06 | $60.24 |

| Relay Sockets | 4 | $10.88 | $43.52 |

| Emergency Stop | 1 | $65.16 | $65.16 |

| Spade Connectors | 1 | $21.84 | $21.84 |

| 24VDC Voltage Converter | 1 | $292.45 | $292.45 |

| Wire | 1 | $5.66 | $5.66 |

| 48VDC Voltage Converter | 1 | $39.89 | $39.89 |

| Solid State Relays (24-380VAC) | 1 | $14.88 | $14.88 |

| Solid State Relay (5-240VDC) | 1 | $9.90 | $9.90 |

| Heater | 1 | $56.07 | $56.07 |

| DC Equipment Cooling Fan | 2 | $312.60 | $625.20 |

| Framing Rail Glide | 2 | $4.18 | $8.36 |

| Panel Slide Track | 1 | $37.67 | $37.67 |

| Corner Bracket | 70 | $7.92 | $554.40 |

| Pull Handle | 1 | $9.82 | $9.82 |

| End-Feed Single Nut | 6 | $7.83 | $46.98 |

| Fasteners | 6 | $6.56 | $39.36 |

| Rail-to-Panel Hinge | 2 | $13.28 | $26.56 |

| Magnetic Door Catch | 1 | $12.49 | $12.49 |

| Aluminum T-Slotted Framing Rails (Single) | 11 | $25.97 | $285.67 |

| Aluminum T-Slotted Framing Rails (Double) | 1 | $49.07 | $49.07 |

| Polyethylene Panel | 2 | $243.51 | $487.02 |

| Polyethylene Panel | 1 | $137.58 | $137.58 |

| Clear Polycarbonate Panel | 1 | $77.71 | $77.71 |

| Rubber Seal | 10 | $5.10 | $51.00 |

| Flat Head Screws | 1 | $9.09 | $9.09 |

| Flange Nut | 1 | $8.57 | $8.57 |

| Silicone Sealant | 1 | $8.96 | 8.96 |

| Total | $4565.66 |

III. Prototype Development & Demonstration

A small-scale prototype validated key design features:

- Adjustable telescoping frame using T-slot aluminum.

- Acrylic panels and seals for insulation.

- GUI integration with Arduino controlling circulation fans.

Prototype demonstrating adjustable depth and GUI-controlled airflow.

Demonstration of the LabVIEW GUI controlling the prototype’s fans.

IV. Project Evaluation

Deliverables Achieved:

- CAD models, design drawings, and assembly documentation.

- GUI control system integrated with prototype hardware.

- Working small-scale prototype verifying key concepts.

- Cost-effective material selection meeting the $5000 target.

Challenges:

- Full-scale high-voltage wiring and heating integration was not completed due to time and safety constraints.

- Some delays from mid-project pivot to scaled prototype procurement.

Despite these, the client’s objectives were met and the foundation for a manufacturable unit was delivered.

V. Future Work & Conclusion

Future improvements include:

- Full-scale build with finalized electrical integration.

- Enhanced safety interlocks and layout optimization.

- Further refinement of airflow modeling for consistent temperature distribution.

Summary:

The redesigned UHB met Juniper’s needs for a modular, cost-effective, and adjustable hotbox design. The prototype validated mechanical and software concepts, with clear next steps for scaling up to a production-ready system.

Key Skills Demonstrated

- Multidisciplinary Collaboration: Worked with Electrical and Computer Engineers on a client-driven design.

- Mechanical Design & CAD: SolidWorks modeling for modular, adjustable structures.

- Tolerance & Fit Considerations: Applied practical clearances in CAD for sliding telescoping shells and component mounting.

- Thermal & Electrical Integration: Coordinated airflow design, power distribution, and safety.

- GUI Development: Programmed LabVIEW interface with Modbus/Arduino integration.

- Cost Reduction & Material Selection: Brought design cost from $20k to under $5k.

- Prototyping: Built and tested proof-of-concept hardware.

- Technical Documentation: Produced drawings, manuals, and wiring diagrams.

- Client Communication: Regular updates and deliverables aligned with Juniper’s expectations.